|

Winmate Bay Trail DIN Rail Box PC

Intel "Bay Trail" Box PC serves as embedded automation controller and, in a special version, for HazLoc market applications

(by Conrad H. Blickenstorfer)

Winmate's IBDRW100 is a compact industrial Box PC that was introduced in late Spring 2015. Designed for a wide variety of industrial automation and machine-to-machine applications, the device is impressively compact — just 2.6 inches wide, 6.0 inches tall, and 5.5 inches deep. That's a frontal area smaller than that of an iPhone 6+. Yet, this is a tough, full-function, Intel Bay Trail-powered industrial Windows computer that's also available with ATEX and C1D2 certification.

The idea and concept of this DIN Rail Box PC is to provide a super-compact industrial PC that provides considerable computing power thanks to its Intel "Bay Trail" Celeron N2930 processor, but without needing a fan. It's also a product with extensive and flexible I/O support for legacy connectivity requiring RS232/485 serial ports with isolation, as well as terminal block digital I/O ports. That's on top of standard USB and gigabit Ethernet connections, as well as up to 256GB of speedy mSATA solid state disks for storage and an additional SATA disk.

Perhaps most intriguingly, this Winmate DIN Rail Box PC was specifically designed for ATEX and C1D2 certification. ATEX (a European directive) certification means a product is safe for use in potentially explosive atmospheres and other hazardous locales. C1D2 refers to a classification used in the North American National Electric Code (NEC); C1D2 (Class 1, Division 2) would apply to areas such as gas stations. In essence, these certifications describe computer systems use in potentially flammable areas where the equipment must under no circumstances generate sparks that could ignite flammable gases. With increasing computer use everywhere, ATEX and C1D2 certification are becoming more and more important, and they are a prerequisite for deployment in industries such as oil, gas, and petrochemical manufacturing, and many others where ignitable gases or vapor may be present.

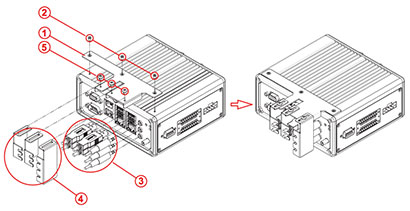

What this means is special designs and precautions, and receiving the all-important ATEX and/or C1D2 certifications. Examples of design considerations include special cable holder methods that preclude the cable/connector movement and friction (and thus possibility for sparking). Winmate's concept is shown below:

Use may also include secure mounting (hence the DIN Rail design), or mounting in specially designed enclosures boxes. The pictures below show an IP54-spec enclosure box Winmate uses for the IBDRW100-EX to meet ATEX and C1D2 certification.

Note that both HazLoc standards have various additional classification criteria such as temperature, explosion groups, protection levels, etc. To get an idea, see this classification reference guide and read the sidebar column.

A few words about Winmate's choice of the Intel N2930 processor, which is part of Intel's "Bay Trail" lineup. Bay Trail is based on a heavily overhauled Atom processor architecture, but that's where the similarity to older Atom CPUs ends. Bay Trail includes Atom, Celeron and even Pentium branded chips. That's somewhat confusing as Intel historically used the Atom brand for its entry level processors, and the Celeron and Pentium brands as the low end of its Core processor lines.

A weakness in most earlier Atom chips was sluggish graphics performance. This has changed in Bay Trail as the platform essentially uses the same integrated Intel graphics technology as in Intel's 3rd generation "Ivy Bridge" Core processors. This also means support for most of the same APIs and features, including DirectX 11, OpenGL 3.X, and OpenCL 1.2.

The quad-core Celeron N2930 chosen by Winmate for this Box PC is a system-on-chip solution that runs at 1.83GHz, has a burst frequency of 2.16GHz, supports fast but efficient DDR3L RAM, and yet still has a Thermal Design Power of just 7.5 watts. This means enough computing and graphics power for numerous target applications, yet in a small-enough thermal envelope to facilitate fanless, sealed operation.

On the memory side, the IB32SB comes with up to 4GB of low voltage DDR3L RAM. Standard mass storage is a 32GB mSATA solid state disk, with 64GB to 256GB options available. The specs do not list expansion via card slots or PCIe connectors.

As far as ruggedness and durability go, embedded industrial systems have different requirements than mobile systems. Vibration and shock resistance are important as industrial mounted systems may be subjected to them. The IBDRW100 and the IBDRW100-EX version can both operate within a very wide temperature range of -4 to 140 degree Fahrenheit, allowing deployment in a very wide range of settings. The Box PCs also pass fairly stringent vibration and shock criteria.

Winmate is a Taiwanese company founded in 1994. Specializing in industrial display technologies and solutions, Winmate also branched out into Tablet PCs, digital signage, rugged Mobile PCs, embedded automation controllers, marine grade displays and computers, and specialty Panel PCs such as the super-compact HazLoc-certifiable DIN Rail Panel PC shown here.

Contact Winmate:

Web: www.winmate.com.tw

Email: sales1 @ winmate.com.tw

OEM/ODM Contact: ODM@winmate.com.tw

|

|

|

Specifications Winmate DIN Rail Box PC Specifications Winmate DIN Rail Box PC

|

|

Status

|

Added 05/2015

|

|

Form-factor

|

DIN Rail Box PC

|

|

OS

|

Windows Embedded Standard 7 or 8.X

|

|

Processor

|

Intel Celeron "Bay Trail" N2930

|

CPU Speed

|

1.83GHz (burst speed up to 2.16GHz)

|

|

Chipset

|

Bay Trail SoC chipset

|

|

Graphics

|

Intel HD Graphics

|

Standard/Max RAM

|

Up to 8GB DDR3L 1333MHz in one SODIMM slot

|

Disk/drive

|

64GB mSATA SSD, optional second storage 64GB to 256GB SATA SSD

|

Card slots

|

Unknown

|

Keyboard/scale

|

Optional external USB keyboard

|

Operating temperature

|

-4° to 140°F (-20° to 60°C)

|

Sealing

|

IBDRW100-EX version required to be used in certified IP54 enclosure

|

Vibration

|

5Hz ~ 500Hz / 1Grms/3 Axis

|

Humidity

|

5 to 95% non-condensing

|

Shock

|

15G, 11ms duration

|

Housing

|

Metal

|

Size (WxHxD)

|

5.5 x 6.0 x 2.6 inches (139 x 152 x 65 mm)

|

Weight

|

Unknown

|

Power

|

9~36V DC IN (Isolation)

|

Interface

|

3 x USB 2.0, 1 x USB 3.0, 1 x RJ45 10/100/1000, 1 x RS232/RS422/485, 1 x RS232/485, 1 x VGA, 1 x 20-pin DIDO terminal block (9in/9out), audio in/out

|

Wireless

|

unknown

|

List price

|

Inquire

|

Web

|

Winmate IBDRW100-EX DIN Rail Bay Trail Box PC

|

Data sheet

|

IBDRW100-EX DIN Rail Box PC spec sheet IBDRW100-EX DIN Rail Box PC spec sheet

|

Winmate Newsletter

|

Introducing Winmate Fanless Intel Bay Trail N2930-powered DIN Rail Box PC Introducing Winmate Fanless Intel Bay Trail N2930-powered DIN Rail Box PC

|

|

|

|

What are "Hazardous Locations"? What are "Hazardous Locations"?

|

|

The term "hazardous location"—or "HazLoc"—originates from electrical engineering where a hazardous location is defined as a place where concentrations of flammable gases, vapors, or dusts occur. Electrical equipment operating in such areas must be designed so that they do not cause combustion or explosions. Devices that fulfill that requirement are described as "intrinsically safe," which means that they are incapable of igniting such gasses, dust or vapors.

As one might expect, there are degrees of intrinsic safety, and there are many different classification systems for various hazardous substances, as well as for the degree of the presence of such substances.

For the classification of rugged computing equipment, manufacturers generally use either the North American National Electric Code (NEC) or the European ATEX directive, or both. ATEX stems from a French expression that includes ATmospheres EXplosives. How do those two entities classify hazardous environments?

NEC first differentiates between

- Class 1 (Flammable gases)

- Class 2 (Flammable dust)

- Class 3 (Flammable fibers)

Each of the classes then is either

- Division 1 (substance present all the time), or

- Division 2 (substance present only for brief time).

A third level (Group) then describes the specific type of gas, dust or fibers.

IEC/ATEX, on the other hand, first differentiates between:

- Flammable gases and vapors ("G"), and

- Flammable dust ("D").

Flammable gases are then assigned:

- Zone 0 (always present)

- Zone 1 (likely present), and

- Zone 2 (occasionally present).

Flammable dust uses

- Zone 20 (always present)

- Zone 21 (likely present), and

- Zone 22 (occasionally present).

Each zone then requires equipment built for

- Category I (present continuously)

- Category II (present intermittently), and

- Category III (occasionally present).

To illustrate how these classification systems apply to real life situations, picture a gas station.

Using the NEC classification, underground gas tanks and tanker truck tanks are Class 1, Division 1; the area around a tanker truck or a gas pump would also be Class 1, Division 1; and the general gas station area is Class 1, Division 2.

Using the IEC/ATEX classification, underground gas tanks and tanker truck tanks are Zone 0, Category I; the area around a tanker truck or a gas pump would be Zone 1, Category I; and the general gas station area is Zone 2, Category 2.

Note that this is an oversimplification; both standards have several additional classification criteria such as temperature, explosion groups, protection levels, etc. (for additional info, check out this classification reference guide).

|

|