Whenever you read about industrial and mobile computers, you will inevitably come across all sorts of ruggedness claims and specifications. Rugged this and rugged that, but what exactly does it mean, and how is "rugged" measured? in general, the term "rugged" in this context describes a computer's ability to withstand the environmental punishment it will likely be subjected to on the job it was built for. "Ruggedness" is measured by any number of military and civilian standards, but it is often quite difficult to figure out what exactly stands behind the boasting on a product spec sheet or marketing materials. In addition, some "rugged" products we've reviewed over the years didn't turn out to be very rugged at all. Inside, some looked more like science projects than serious industrial equipment.

Over the last decade or two I had a chance to personally see the ruggedness testing facilities of some of the industry's leading vendors and manufacturers. I spent a day at what was then Intermec's Norand Mobile Systems Division In Cedar Rapids, Iowa. I saw Panasonic's environmental testing lab for its Toughbook computers outside of Kobe, Japan. And I had a tour of Intermec's testing facilities in Spokane, Washington.

Over the last decade or two I had a chance to personally see the ruggedness testing facilities of some of the industry's leading vendors and manufacturers. I spent a day at what was then Intermec's Norand Mobile Systems Division In Cedar Rapids, Iowa. I saw Panasonic's environmental testing lab for its Toughbook computers outside of Kobe, Japan. And I had a tour of Intermec's testing facilities in Spokane, Washington.

When I was given the tour of Intermec's facility, I had never actually seen a ruggedness testing lab and thought that most manufacturers probably sent their equipment to some remote lab for testing and then get it back with a seal of approval from the lab. That was definitely not the case at Intermec. I had no idea to what extent Intermec went to ensure that each of its products was fit for the job.

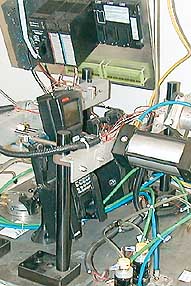

Intermec's testing lab filled the basement of an entire building and could not be described as anything but a torture chamber or dungeon for electronic equipment. There were dozens of test stations designed to subject a computer to just about any kind of punishment conceivable, and then some. There were salt spray chambers to determine resistance to corrosion. There were ovens were computers were baked, cooled down and then baked again. There were several vibration tables that helped to determine what, if anything, might shake loose in, say, a utility truck with busted shock absorbers. There was a totally radio-silent room that looked like something out of Star Trek.

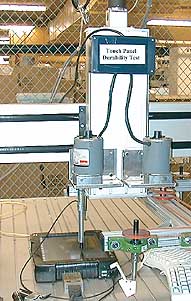

Some of the testing stations were almost comical, such as a rain resistance chamber where a poor little Intermec handheld computer took an extended shower. Others looked downright spooky, like machines that automatically depressed all the buttons on an Intermec terminal thousands of times, or one that endlessly "wrote" on the touch screen of another Intermec product. I also learned how, exactly, they do those "repeated drops onto a hard surface."

Some of the testing stations were almost comical, such as a rain resistance chamber where a poor little Intermec handheld computer took an extended shower. Others looked downright spooky, like machines that automatically depressed all the buttons on an Intermec terminal thousands of times, or one that endlessly "wrote" on the touch screen of another Intermec product. I also learned how, exactly, they do those "repeated drops onto a hard surface."

At Panasonic's computer manufacturing plant in Japan I saw an even bigger lab for the testing of the company's Toughbook line of rugged notebooks. Plant Manager Mr. Masayuki Kitabayasi personally showed me the entire range of torture testing performed in his facility. Those tests were done according to both Japanese and US testing procedures, and the products underwent independent testing in addition. In the US, I was told, yet more tests are done by the Southwest Research Institute in San Antonio (www.swri.org), a non-profit testing agency whose clients include NASA and US auto manufacturers.

Manufacturers may actually do additional testing for specific clients with specific needs. For example, the US Coast Guard was interested in Panasonic Toughbooks, but was concerned about the extended exposure to saltwater. Panasonic subjected its products a special battery of saltwater tests. Those tests resulted in substantial corrosion and salt build-up, which Panasonic freely showed me. Engineers then went back to the drawing board to create a special model for the USCG that could stand up to use in saltwater environments. That included special paints, anti-corrosive greasing and coating, stainless steel screws, airtight gaskets, and sophisticated chemical counter measures against electric corrosion. When I was there, the re-tests were still underway, but preliminary results showed great improvements, and also Panasonic's willingness to adapt and push their technology to a customer's needs.

Manufacturers may actually do additional testing for specific clients with specific needs. For example, the US Coast Guard was interested in Panasonic Toughbooks, but was concerned about the extended exposure to saltwater. Panasonic subjected its products a special battery of saltwater tests. Those tests resulted in substantial corrosion and salt build-up, which Panasonic freely showed me. Engineers then went back to the drawing board to create a special model for the USCG that could stand up to use in saltwater environments. That included special paints, anti-corrosive greasing and coating, stainless steel screws, airtight gaskets, and sophisticated chemical counter measures against electric corrosion. When I was there, the re-tests were still underway, but preliminary results showed great improvements, and also Panasonic's willingness to adapt and push their technology to a customer's needs.

My trip to Itronix in Spokane revealed another sophisticated environmental testing lab with many specialized tools and lots of one-of-a-kind equipment. The testing lab itself, the "torture chamber," subjects Itronix computers to temperature extremes, shock, moisture, humidity, stress and just about anything else an Itronix device might encounter on the job.

Itronix also had a very advanced radio testing lab with plenty of equipment to optimize all components and finding the best antennas. In-house testing of radio performance served as a way to minimize costs by increasing the chance of passing the stringent externally performed FCC certifications. "We make sure they pass," noted the managed in charge with pride.

For a good demonstration of what ruggedness testing is all about, MobileDemand of Cedar Rapids, Iowa, prepared a number of videos. You can see screenshots and video links by clicking here.

Where it gets complicated is in translating the results of the tests into numbers and ratings that quickly convey a device's overall ruggedness. The military has exceedingly detailed standards (MIL-SPEC) that describe exactly how tests are to be performed. Canada has its own testing procedures, and so do other industrialized nations. A product's specification sheet may therefore contain a reference that it has passed this and that test--not something that most people can easily interpret.

Fortunately, there are some simple rating systems that at least can provide a "big picture idea of how rugged a piece of equipment is. One such system is the IEC (International Electrotechnical Commission) Ingress Protection rating that condenses sealing against solids and liquids into a simple two digit number, like IP-65 (see Definitions & Specs section).

Fortunately, there are some simple rating systems that at least can provide a "big picture idea of how rugged a piece of equipment is. One such system is the IEC (International Electrotechnical Commission) Ingress Protection rating that condenses sealing against solids and liquids into a simple two digit number, like IP-65 (see Definitions & Specs section).

What's the bottomline? If you are in the market for rugged hardware, first determine exactly how much abuse the equipment needs to be able to take. Asking for too much protection simply raises the price without additional benefits. Asking for too little will result in high failure rates. Once that is done, peruse the market for suitable vendors and contact them to discuss your specific requirements. If they are serious, they will have very detailed answers and very detailed data. Accept nothing less.

--Conrad H. Blickenstorfer

Over the last decade or two I had a chance to personally see the ruggedness testing facilities of some of the industry's leading vendors and manufacturers. I spent a day at what was then Intermec's Norand Mobile Systems Division In Cedar Rapids, Iowa. I saw Panasonic's environmental testing lab for its Toughbook computers outside of Kobe, Japan. And I had a tour of Intermec's testing facilities in Spokane, Washington.

Over the last decade or two I had a chance to personally see the ruggedness testing facilities of some of the industry's leading vendors and manufacturers. I spent a day at what was then Intermec's Norand Mobile Systems Division In Cedar Rapids, Iowa. I saw Panasonic's environmental testing lab for its Toughbook computers outside of Kobe, Japan. And I had a tour of Intermec's testing facilities in Spokane, Washington.

Some of the testing stations were almost comical, such as a rain resistance chamber where a poor little Intermec handheld computer took an extended shower. Others looked downright spooky, like machines that automatically depressed all the buttons on an Intermec terminal thousands of times, or one that endlessly "wrote" on the touch screen of another Intermec product. I also learned how, exactly, they do those "repeated drops onto a hard surface."

Some of the testing stations were almost comical, such as a rain resistance chamber where a poor little Intermec handheld computer took an extended shower. Others looked downright spooky, like machines that automatically depressed all the buttons on an Intermec terminal thousands of times, or one that endlessly "wrote" on the touch screen of another Intermec product. I also learned how, exactly, they do those "repeated drops onto a hard surface."

Manufacturers may actually do additional testing for specific clients with specific needs. For example, the US Coast Guard was interested in Panasonic Toughbooks, but was concerned about the extended exposure to saltwater. Panasonic subjected its products a special battery of saltwater tests. Those tests resulted in substantial corrosion and salt build-up, which Panasonic freely showed me. Engineers then went back to the drawing board to create a special model for the USCG that could stand up to use in saltwater environments. That included special paints, anti-corrosive greasing and coating, stainless steel screws, airtight gaskets, and sophisticated chemical counter measures against electric corrosion. When I was there, the re-tests were still underway, but preliminary results showed great improvements, and also Panasonic's willingness to adapt and push their technology to a customer's needs.

Manufacturers may actually do additional testing for specific clients with specific needs. For example, the US Coast Guard was interested in Panasonic Toughbooks, but was concerned about the extended exposure to saltwater. Panasonic subjected its products a special battery of saltwater tests. Those tests resulted in substantial corrosion and salt build-up, which Panasonic freely showed me. Engineers then went back to the drawing board to create a special model for the USCG that could stand up to use in saltwater environments. That included special paints, anti-corrosive greasing and coating, stainless steel screws, airtight gaskets, and sophisticated chemical counter measures against electric corrosion. When I was there, the re-tests were still underway, but preliminary results showed great improvements, and also Panasonic's willingness to adapt and push their technology to a customer's needs.

Fortunately, there are some simple rating systems that at least can provide a "big picture idea of how rugged a piece of equipment is. One such system is the IEC (International Electrotechnical Commission) Ingress Protection rating that condenses sealing against solids and liquids into a simple two digit number, like IP-65 (see

Fortunately, there are some simple rating systems that at least can provide a "big picture idea of how rugged a piece of equipment is. One such system is the IEC (International Electrotechnical Commission) Ingress Protection rating that condenses sealing against solids and liquids into a simple two digit number, like IP-65 (see