|

|

Ruggedizing Capacitive Touch for Industrial Computing

Upgrading from resistive touch screen technology to capacitive could bring a whole host of benefits to industrial computers, but only if the screens can be ruggedized.

by Christian Funk, September 2015

Touch screen technology is found in pretty much all types of consumer electronics devices today, from smartphones and tablets to home appliances. It's so widespread that the vast majority of consumers today intuitively understand how to operate a touch screen. OEMs in every consumer segment are seeing the benefits of a new level of flexibility for human machine interfaces that couldn't be done with buttons or keypads, as it enables them to add richer features to electronic devices without compromising on ease of use or aesthetically pleasing design.

Touch screen technology is found in pretty much all types of consumer electronics devices today, from smartphones and tablets to home appliances. It's so widespread that the vast majority of consumers today intuitively understand how to operate a touch screen. OEMs in every consumer segment are seeing the benefits of a new level of flexibility for human machine interfaces that couldn't be done with buttons or keypads, as it enables them to add richer features to electronic devices without compromising on ease of use or aesthetically pleasing design.

Outside of consumer electronics, the industrial computing sector could also use the advantages of touch screen interfaces, but the standard capacitive touch technology used in typical portable electronic devices unfortunately isn't suited to the industrial environment. Portable consumer devices are designed to be as lightweight as possible, and therefore use thin layers of glass which are easily broken if dropped. Since consumer device capacitive touch relies on sensing a conductive object in contact with the sensor, these screens can't be used with gloves, a problem in many industrial environments. Capacitive touch screens also struggle when used in wet environments and any sort of significant spillages can be fatal.

Limitations of resistive touch

For these reasons, until now the industrial computing sector has stuck with resistive touch technology, which can be made more rugged than consumer capacitive touch screens. Resistive touch sensors use a plastic surface, which although more durable than ordinary glass, is still prone to breakages, scratches and scuffs. The plastic surface can't be made thicker because it needs to be physically deformed when touched in order to register a touch. However, it can be used with gloves, or with a stylus for detailed and accurate input, since any object touching the screen will register a touch.

Resistive touch screens' lack of durability is a real problem outside the consumer sector, because practically all other parts of an electronic system can be made significantly more rugged through specially designed shock proof and waterproof casings and seals. The resistive touch screen in many designs is therefore the point of failure for the device, directly responsible for device down time while it is being repaired.

Another disadvantage to resistive technology is that the general public is now extremely familiar with capacitive technology. Users have experienced the light touch that capacitive touch sensors require, the gesture functionality they allow (such as pinching and swiping) and their overall extremely quick and responsive nature. Since resistive touch technology can't match these features, the user experience can be disappointing by comparison. Industrial and other sectors with challenging operating environments would therefore like to switch to capacitive technology to improve user experience, but until now, rugged versions of this technology haven't existed.

Enter PCT — projected capacitive touch

Projected capacitive touch (PCT) is fairly new to the industrial computing market. It's a variation of consumer device capacitive touch sensing technology that has all the benefits of its consumer counterpart, but works in a modified way, allowing the display to be ruggedized.

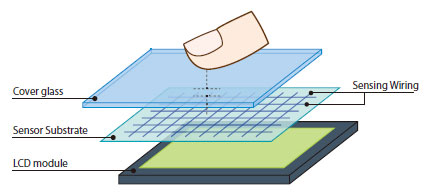

PCT uses a matrix of electrodes to detect a touch. When the user's finger (or a conductive stylus) approaches the glass, the change in the electromagnetic field surrounding the electrodes is disturbed, changing the electrodes' capacitance, which can be detected by some control circuitry. PCT uses a matrix of electrodes to detect a touch. When the user's finger (or a conductive stylus) approaches the glass, the change in the electromagnetic field surrounding the electrodes is disturbed, changing the electrodes' capacitance, which can be detected by some control circuitry.

Crucially, industrial PCT doesn't necessarily require direct contact between the user's finger and the touch sensor, meaning that the sensor can be placed behind a protective layer of toughened glass to ensure durability, shock and scratch proofing (see figure on the right).

JLT's Rugged PCT

JLT Mobile Computing's implementation of the technology, called Rugged PCT, uses chemically toughened glass with a thickness of 1.8mm. This is thick enough to withstand the impact from a 500 gram (1.1 lb) steel ball dropped from a height of 1.2 meters (4 feet) without any damage, while being thin enough to minimize the distance between the surface and the LCD display to eliminate any optical parallax error. It weighs only a little more than a plastic surface of the same thickness.

But it's not just about strength

Despite this breakthrough, early implementations of industrial PCT technology, although mechanically durable, still struggled with interference from other conductive objects in the vicinity of the sensor, including water droplets. That's because ruggedizing the touch sensor is not only about physical strength. Despite this breakthrough, early implementations of industrial PCT technology, although mechanically durable, still struggled with interference from other conductive objects in the vicinity of the sensor, including water droplets. That's because ruggedizing the touch sensor is not only about physical strength.

JLT's Rugged PCT uses advanced control firmware which is able to filter out unwanted signals that may otherwise register false touches. For example, it can filter out a signal produced by the user's palm touching the display surface. It is also smart enough to discount signals from water droplets in the environment, or water spilled onto the screen.

When incorporating Rugged PCT into products, such as the JLT1214P logistics computer (see image on the right), innovative design techniques were also used to ensure the metal chassis of the case, essential for mechanical protection of the computer, doesn't come too close to the touch sensor as it can cause interference.

Minimized bezel

The case of the JLT1214P computer is also designed with a minimal plastic extrusion surrounding the protective glass, ensuring shock proof construction from side impacts while minimizing any cavities or gaps that dirt can collect in. This is beneficial for industries such as food production, in which the equipment must be sanitized daily.

Maximized light transmission

Instead of the transparent conductive film electrodes used by many types of PCT sensor, Rugged PCT uses a grid of extremely fine wires embedded in the sensor, which are almost invisible to the naked eye. Transparent conductive films, such as indium tin oxide (ITO) can cause a perceptible color shift and reduce the brightness of the screen overall. Since the user is effectively looking straight through the grid of fine wires, Rugged PCT maximizes light transmission and minimizes any visual effect of adding the touch sensor over the LCD.

Multi-touch

Another benefit of PCT is that it can support the multi-touch functionality that consumer devices offer. Rugged PCT offers dual touch capability which can be used to implement familiar functions such as pinch to zoom. It can also offer gestures such as swipe to scroll. While application software in the industrial computing industry may not support these features just yet, now that the hardware can support them while maintaining a suitably rugged form factor, they are available for future generations of software to take advantage of. In the meantime, Rugged PCT works just fine with existing single touch application software.

While Rugged PCT can be used with a stylus, capacitive stylus designs are typically larger and blunter than their resistive counterparts, meaning resistive technology still has the edge in applications that require a fine stylus for detailed, accurate information entry such as editing spreadsheets. However, this represents only a minority of industrial use cases. Resistive may also be suitable for any remaining low end or very cost conscious applications.

PCT — a realistic alternative to resistive touch

Overall, advances in ruggedizing PCT technology, such as Rugged PCT from JLT Mobile Computers, have brought capacitive touch to the industrial sector as a realistic alternative to resistive touch. Rugged PCT combines extremely durable, reliable, rugged technology with water resistant properties, interference-proof design and compatibility with gloved use. The touch screen is no longer the most vulnerable part of an industrial computer; the screen can last as long as the computer itself, minimizing down time and increasing productivity, while bringing the intuitive and responsive user experience that consumer devices offer to the industrial arena.

Christian Funk Sales and Marketing Director of JLT Mobile Computers, a leading developer of rugged mobile computers for demanding environments. He has been with JLT Mobile for over 20 years in managerial positions. Mr. Funk's educational background is in electronic engineering.

|